The CVAC hose inlet mounted next to or attached with the power unit is often called a “utility inlet”. These inlets are often promoted as an easy option for cleaning in the garage or basement where many vacuum system power units are mounted. Today the utility inlet is promoted as an important feature of central vacuums, but that is not how they started.

The CVAC hose inlet mounted next to or attached with the power unit is often called a “utility inlet”. These inlets are often promoted as an easy option for cleaning in the garage or basement where many vacuum system power units are mounted. Today the utility inlet is promoted as an important feature of central vacuums, but that is not how they started.

The utility inlet was originally devised for maintenance of the vacuum system itself. Many of the first consumer central vacuums used cyclonic separation which is unfortunately quite messy when it comes time for regular emptying of the bin. The separation cone, filter screen and internal shrouds are all places where dirt and dust will accumulate and during maintenance when the bin is removed these soils often fall out of the vacuum.

For some of us a little dirt on the garage floor is not exactly new. Some cyclonic vacuum system owners keep a garbage can with liner sitting just under the vacuum at all times. This will catch most of the debris that might fall out of the vacuum during maintenance of the bin and the filter screen in cyclonic vacuums, and gives you a convenient place to dump the bin when full. If your messy cyclonic central vacuum has a utility inlet you need only hook up your hose to recover escaped debris once your bin is reattached to the vacuum and your filter screen has been cleaned.

Aspria Vacuums offers the more advanced permanent filter system or sealed bag collection system, both of which keep their dust in the bin or bag during regular maintenance and not on the floor. Instead of permanently mounting the utility intake into the front of the vacuum, Aspria includes an inline switched utility inlet that allows you to place the valve where it is best for you. Often our clients find it best to mount the utility inlet near a garage door which allows cleaning of one or two cars in the garage and one in the drive all from the same inlet while keeping your vacuum mounted nearer to the front of the garage out of the way of traffic and away from any weather that may come in from an open garage door.

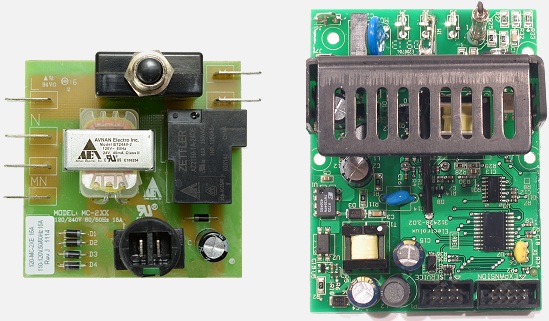

Aspria GQ and HHQ series also include optional intake mounted utility inlets when used in bagless collection mode that allows installation of the utility inlet directly into the body of the vacuum along (old-school style) with the inline mounting option included with all models of Aspria vacuum. A built-in utility inlet may have been more useful in the older cyclonic separation design than newer permanent filtered or bagged vacuums but we like the idea of giving the client all options and letting the client decide which is best for their home.

The products and services of the aspria.systems website are now available at Central Vacuum Stores.

The products and services of the aspria.systems website are now available at Central Vacuum Stores.

Installing a central vacuum system in a new or pre-existing home is an easy process in most cases that can be completed in one or two days. Adding a central cleaning system to a residence not only makes cleaning more efficient and convenient, but also adds value to the home that is often 2 – 4 times the initial cost of equipment. Central cleaning is the choice for those who want more power, better filtration and the reliability of a built-in appliance that can not be found in a portable upright or canister vacuum.

Installing a central vacuum system in a new or pre-existing home is an easy process in most cases that can be completed in one or two days. Adding a central cleaning system to a residence not only makes cleaning more efficient and convenient, but also adds value to the home that is often 2 – 4 times the initial cost of equipment. Central cleaning is the choice for those who want more power, better filtration and the reliability of a built-in appliance that can not be found in a portable upright or canister vacuum. This is it! You have found the article that holds the keys to discovering Which Central Vacuum Is Best. We will not waste your time with a Top 10 Central Vacuum Systems which we want to sell, there are plenty of those on the internet and they do little good. This is a central vacuum buyers guide to-do list. We will review central vacuum system design and components from a professionals perspective to help you find the best, so get your pen handy or bookmark this page. This insightful and straightforward advice is available free for the reading and will be helpful on your Best Central Vacuum search.

This is it! You have found the article that holds the keys to discovering Which Central Vacuum Is Best. We will not waste your time with a Top 10 Central Vacuum Systems which we want to sell, there are plenty of those on the internet and they do little good. This is a central vacuum buyers guide to-do list. We will review central vacuum system design and components from a professionals perspective to help you find the best, so get your pen handy or bookmark this page. This insightful and straightforward advice is available free for the reading and will be helpful on your Best Central Vacuum search.